Researchers Take Body Armor to the Next Level with High Energy Fibers

Current body armor is heavy, cumbersome, and way above the desired aerial density, which limits mobility and physical performance of soldiers.

It sounds like something out of the movie “Iron Man,” where the fictional American superhero builds an armored suit to fight terrorists and overturn his captors. For   researchers at Florida Atlantic University’s , developing and enhancing materials to improve the performance of military helmets and body armor is definitely not fictional. They have received $569,482 from the (CTTSO) under the advanced Armor Materials ŕŁŕŁÖ±˛ĄĐă, to develop advanced fibers for body armor. Ballistic or bullet-proof armor performance is heavily dependent on the base material properties, which have changed little in recent years.Â

The CTTSO identifies and develops capabilities to combat terrorism at home and abroad and irregular adversaries and to deliver these capabilities to United States Department of Defense components and interagency partners through rapid research and development, advanced studies and technical innovation, and provision of support to U.S. military operations.

“Composite fiber plays a very important role in the performance of ballistic armor, and its mechanical properties are integrally related with kinetic energy absorption and dissipation,” said , Ph.D., dean of FAU’s College of Engineering and Computer Science. “However, in recent years there have not been any significant advances in ballistic fiber properties, resulting in limited improvements of armor performance. With this important effort, our researchers will be able to enhance the properties of the fiber that will potentially lead to greater energy absorption and ballistic performance, and ultimately, greater protection of the women and men who serve in the United States military.”Â

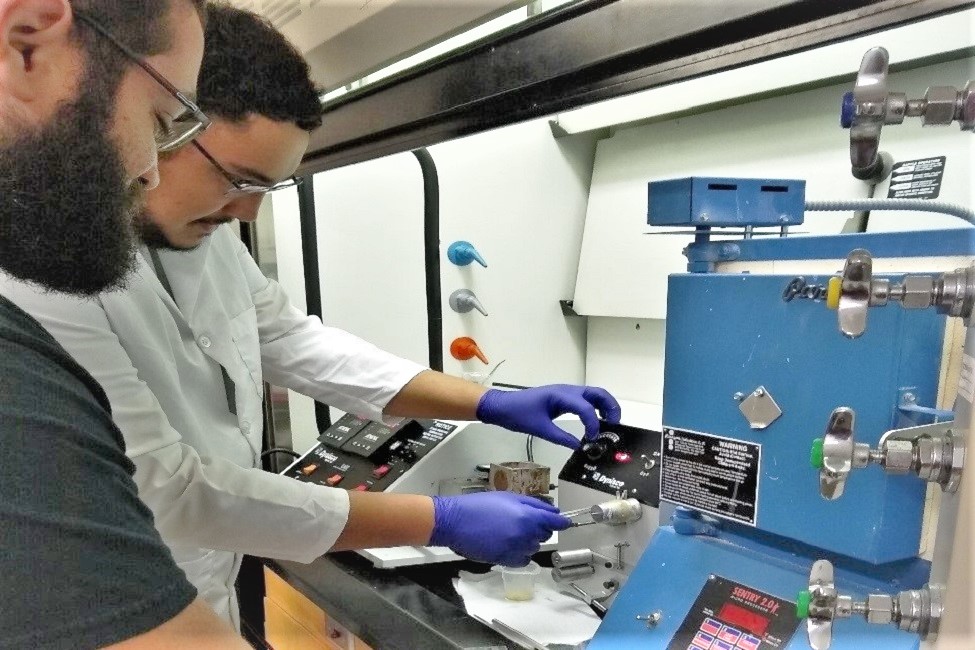

The fibers in an armor absorb ballistic energy and dissipate it as quickly as possible when the projectile strikes. Fiber strength, modulus and fracture strain are key parameters for absorption and dissipation. FAU’s two-year project, “Hybridization of Ultrahigh Molecular Weight Polyethylene (UHMWPE) with Nylon and Carbon Nanotubes for Improved Ballistic Performance,” is aimed at improving the properties of UHMWPE fibers that are used in ballistic applications. The project involves two phases consisting of both experimental and computational approaches to investigate manufacturing, testing, and predicting the performance of the modified fiber. Testing of fibers will be performed at various rates of strain ranging from quasi-static to ballistic.

“Although current body armor provides increasingly advanced protection to our soldiers, it comes at a cost. It’s heavy, cumbersome, and way above the desired aerial density, which limits mobility and physical performance of our soldiers,” said , Ph.D., principal investigator, an expert in nanocomposite and structured materials and a professor in FAU’s . “For more than a decade, considerable efforts have been made in carrying out various experimental, analytical and numerical investigations to identify and explain penetration-failure mechanisms under ballistic loading. We are hopeful the hybridized nanocomposite fiber we are developing will help to take body armor to the next level. We expect that it will possess excellent strength, modulus and fracture strain, which will lead to high energy absorption, and fast dissipation.”

The FAU project is led by Mahfuz, , Ph.D., a professor and an expert in robotics, rehabilitation engineering, and computerized manufacturing; and , Ph.D., the J.M. Rubin Foundation Professor and an expert in composite materials and solid mechanics, both in FAU’s Department of Ocean and Mechanical Engineering, in collaboration with the , and .

-FAU-

Tags: science | military | faculty and staff | engineering | research | ŕŁŕŁÖ±˛ĄĐă | technology